The 750-900t/h hard rock crushing plant represents the pinnacle of high-capacity processing for heavy-duty mining and construction operations. With its ability to crush large volumes of tough rock materials, this plant is engineered for maximum efficiency and reliability, even in the most demanding environments.

Boasting advanced features such as enhanced automation, low maintenance requirements, and energy-efficient operation, the 750-900t/h crushing plant is designed to minimize downtime, reduce operational costs, and increase the overall throughput of your production line. This makes it the ideal choice for large-scale projects that require both performance and cost-effectiveness.

With its capacity to process between 750 and 900 tons per hour, the 750-900t/h hard rock crushing plant is a high-capacity solution for mining and aggregate production. This plant is engineered to handle extremely tough materials such as hard rock, granite, and metal ores, making it perfect for large-scale operations where high throughput is essential.

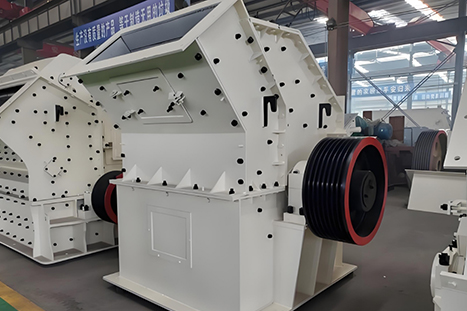

The plant's robust construction ensures durability even under continuous heavy-duty operation, while its advanced crushing technology delivers consistent, high-quality material outputs. The powerful crushers within the plant provide reliable performance and ensure high-efficiency processing, minimizing energy consumption while maximizing productivity.

The 750-900t/h hard rock crushing plant is built for reliability and ease of maintenance. Featuring advanced automation systems, it requires minimal manual intervention, reducing labor costs and downtime. The plant’s components are designed for easy access and quick replacement, ensuring fast repairs and continuous operation. Its high-efficiency motors and hydraulic systems contribute to reduced energy consumption, lowering overall operating costs for your facility.

Whether it’s used for mining operations, aggregate production, or construction projects, this crushing plant offers great versatility. It can process a wide range of materials, from hard rocks and ores to construction aggregates, making it an essential asset for companies looking to boost their production capacity without compromising on efficiency.

One of the key advantages of the 750-900t/h hard rock crushing plant is its ability to provide a high return on investment. By optimizing processing efficiency and reducing downtime, it helps to lower operational costs, making it a cost-effective choice for large-scale operations. Its versatility allows it to adapt to different project needs, whether it's in mining, infrastructure development, or aggregate production.

With its ability to scale to higher production volumes and process more materials per unit time, the plant supports companies in meeting their growing production demands while maintaining optimal operational efficiency. The modular design also allows for future upgrades and easy integration into existing production lines, providing long-term value for any business.

We assign a project manager for each project, who provides specialized project management services, including strict project stage progress management to ensure on-schedule project completion. Strict internal production management ensuring on-schedule production completion.

We provide complete installation services for customers regarding site leveling, foundation drawing inspection, construction progress and team planning, installation instructions, and production line commissioning, to ensure smooth operation of production lines. In addition, we provide appropriate trainings for customers to achieve their satisfaction.

Integrating R&D, production, distribution, and service-providing into one enterprise, HAMAC attaches great importance to communication with customers. We have established an after sales visit team consisting of more than 68 persons. On the one hand, they timely solve the problems that our customers encounter; on the other hand, they collect feedback and improvement recommendations from our customers, to correctly orient our development and research.