The 300-350t/h soft rock crushing plant is optimized for large-scale aggregate production, designed to handle materials such as limestone, gypsum, and dolomite. With advanced equipment, it ensures efficient processing, delivering high-quality aggregates for construction projects.

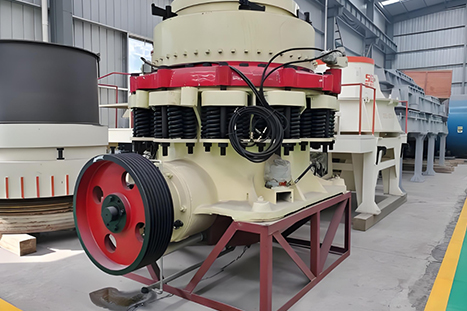

This plant includes robust machinery like jaw crushers, cone crushers, and vibrating screens, which are specifically designed to process soft rock materials efficiently. It is engineered to maximize production while minimizing energy consumption and maintenance costs, making it a cost-effective choice for aggregate processing.

The plant configuration includes several essential machines to ensure smooth and efficient operation:

This equipment setup ensures optimal performance, leading to higher output and minimal operational interruptions.

The 300-350t/h soft rock crushing plant offers a competitive investment return due to its high processing capacity and low operational costs. The typical investment ranges from $150,000 to $220,000, depending on the selected equipment and plant configuration. The combination of advanced machinery and low energy consumption ensures a rapid return on investment for businesses looking to scale up their production capacity.

We assign a project manager for each project, who provides specialized project management services, including strict project stage progress management to ensure on-schedule project completion. Strict internal production management ensuring on-schedule production completion.

We provide complete installation services for customers regarding site leveling, foundation drawing inspection, construction progress and team planning, installation instructions, and production line commissioning, to ensure smooth operation of production lines. In addition, we provide appropriate trainings for customers to achieve their satisfaction.

Integrating R&D, production, distribution, and service-providing into one enterprise, HAMAC attaches great importance to communication with customers. We have established an after sales visit team consisting of more than 68 persons. On the one hand, they timely solve the problems that our customers encounter; on the other hand, they collect feedback and improvement recommendations from our customers, to correctly orient our development and research.